|

Baoji Yinggao Metal Materials Co., Ltd.

|

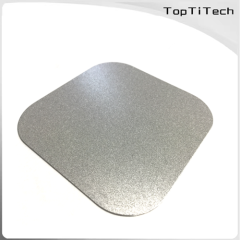

M20 Connector Titanium Powder Sintered Filter Cartridge

| Price: | 15.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU,Paypal,Money Gram |

| Place of Origin: | Shaanxi, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Material: titanium powder

Size: 50*400mm

Pore size: 1micron

Temperature resistance: ≤300℃

Pressure resistance: ≤Mpa3.0

M20 Connector Titanium Powder Sintered Filter Cartridge

The M20 connector titanium powder sintered filter cartridge is a type of filter material made through the sintering process using titanium powder. It typically has an M20 connector and is suitable for various filtration equipment and systems.

The M20 connector titanium powder sintered filter cartridge is known for its high filtration efficiency, high temperature and corrosion resistance, long lifespan, and cleanability, making it widely used in liquid filtration applications across industries such as chemical, food, pharmaceutical, and electronics.

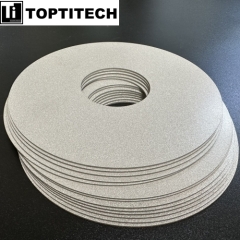

Parameters

Material: titanium powder

Size: 50*400mm

Pore size: 1micron

Temperature resistance: ≤300℃

Pressure resistance: ≤Mpa3.0

Features

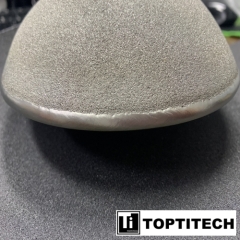

High Filtration Efficiency: The M20 connector titanium powder sintered filter cartridge offers a high level of filtration efficiency, effectively removing fine particles, suspended solids, and impurities. Its porous structure and small pore size provide excellent filtration performance.

High Temperature and Corrosion Resistance: Titanium material exhibits excellent high temperature and corrosion resistance properties. The M20 connector titanium powder sintered filter cartridge can operate stably in high-temperature and corrosive media, making it suitable for demanding industrial environments.

Long Lifespan and Cleanability: The M20 connector titanium powder sintered filter cartridge has a long service life and can be extended through cleaning and restoration operations. Its cleanability allows for cost-effective and environmentally friendly use.

High Flow Rate and Low Pressure Drop: The M20 connector titanium powder sintered filter cartridge features a large filtration area and porosity, enabling high flow rates. Additionally, its excellent flow characteristics minimize filtration pressure drop, reducing energy consumption.

Applications

Chemical Industry: The M20 connector titanium powder sintered filter cartridge is widely used in the chemical industry for filtering acids, alkalis, solvents, and other corrosive media to protect equipment and improve product quality.

Food and Beverage Industry: The M20 connector titanium powder sintered filter cartridge is employed in liquid filtration applications within the food and beverage industry to remove suspended solids, particles, and microorganisms, ensuring product purity and safety.

Pharmaceutical Industry: In the pharmaceutical industry, the M20 connector titanium powder sintered filter cartridge is used for filtering raw materials, intermediate products, and final products, guaranteeing cleanliness and purity.

Electronics Industry: The M20 connector titanium powder sintered filter cartridge finds application in the electronics industry for filtering plating solutions, etching solutions, and other process liquids, removing impurities and particles to enhance product quality.

When cleaning and backwashing the filter cartridge, the following points should be noted:

Use the appropriate cleaning agents: Select suitable cleaning agents that are effective in removing contaminants without damaging the filter cartridge's performance. Adhere to the safety instructions provided for the cleaning agents.

Control cleaning temperature and time: Ensure thorough removal of contaminants while avoiding excessive thermal stress by controlling the cleaning temperature and time. Select the recommended temperature and cleaning duration based on the cleaning agent's guidelines.

Choose suitable cleaning methods: Select the appropriate cleaning method based on the filter cartridge's specific characteristics. Methods such as immersion, backwashing, ultrasonic cleaning, or mechanical brushing can be employed to achieve comprehensive cleaning of all surfaces and pores.

Prevent mechanical damage: Avoid direct contact between the filter cartridge and sharp or hard objects during the cleaning process to prevent surface scratches or structural damage. Utilize appropriate tools and techniques, applying moderate force.

Thorough rinsing and drying: After cleaning, thoroughly rinse the filter cartridge to remove all cleaning agents and contaminants. Follow proper drying procedures to prevent moisture retention inside the filter cartridge, which could lead to bacterial growth or other issues.