|

Baoji Yinggao Metal Materials Co., Ltd.

|

0.2 micron titanium sintered filter for ozone aeration

| Price: | 20.0 USD |

| Payment Terms: | T/T,Paypal |

| Place of Origin: | Shaanxi, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Diameter: 50mm

Length: 100mm

Connector: 2 sides open

pore size: 0.2 micron

Technique: powder sintering

0.2 micron titanium sintered filter for ozone aeration

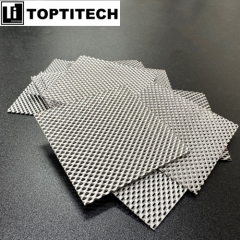

TOPTITECH's 0.2 micron titanium sintered filter element is designed for ozone aeration and has excellent filtration performance and durability. This feature allows the product to shine in various industrial sectors, whether in high-pressure gas filtration or highly corrosive liquid handling, demonstrating robust reliability.

The production principle of the 0.2 micron titanium sintered filter element is to use Gr1 titanium powder as the raw material, cold isostatic pressing, and then high-temperature vacuum sintering in a vacuum furnace, and finally cutting and other subsequent processes for finished product processing.

Parameters

Diameter: 50mm

Length: 100mm

Connector: 2 sides open

pore size: 0.2 micron

Technique: powder sintering

Features

Uniform porous structure: Through precise manufacturing with Gr1 titanium powder, our filter exhibits a uniform micro-pore structure, ensuring efficient filtration. Each pore is consistently sized to guarantee material consistency and reliability.

Corrosion resistance: This titanium sintered filter demonstrates excellent corrosion resistance, enabling prolonged usage in harsh environments without degradation. It is well-suited for filtering /or liquids containing corrosive components.

Uniform and fine bubble generation: 0.2 micron titanium sintered filter element performs well in ozone aeration applications and can produce uniform and fine bubbles. These tiny bubbles have a large surface area, which increases the contact area between gas and liquid, promotes the efficiency of material transfer between gas and liquid, and improves the reaction effect.

Long life and durability: This titanium sintered filter element is known for its excellent durability and long life. Its unique sintering process gives it excellent mechanical strength and durability, able to withstand high pressure and frequent cleaning requirements. This durability not only extends the service life of the filter element, but also reduces replacement and maintenance costs, bringing greater economic benefits to customers.

Applications

Food and Beverage Industry: In food production and beverage processing, this filter element can be used to remove suspended particles, microorganisms and odorous substances to ensure the hygiene safety and taste quality of the product. Its corrosion resistance and high-efficiency filtration performance make it an ideal choice for the food industry.

Biomedical field: In biomedical research and production, this filter element can be used to separate and purify biological products such as proteins and cell culture media. Its reusable characteristics and efficient microporous structure provide reliable support for biomedical applications, ensuring the purity and quality of the product.

Environmental Engineering: In the field of environmental engineering, 0.2 micron titanium sintered filter elements can be used in flotation systems in water treatment equipment. By generating uniform and fine bubbles, the flotation efficiency can be effectively improved, and suspended matter and pollutants in the water body can be removed, thereby purifying the water quality.

Sewage treatment: In the sewage treatment process, this filter element can be used in aeration tanks or aeration pipes to help improve oxygen transfer efficiency and gas-liquid reaction rate. By increasing the gas-liquid contact area and refining the bubble size, it helps to degrade organic matter and reduce the nitrogen content, improving the efficiency and quality of sewage treatment.